In industrial automation, we install and program many servo motors and drive in industries every day and so sometimes it becomes very problematic to set each and every drive with the display panel. So to make this an easy process, you can also use servo drive software to make changes or set new parameters through your laptops. Today let me tell you about CX drive, which is Omron product and by which you can program your drive without touching display panel. Almost all the automation product manufacturing company provide servo drive software so you can check with your drive provider. Subscribe to Automation-Talk by Email.

Required Conditions

1. You must have CX-Drive installed on your laptops/desktops.

2. Servo drive should be connected to set or change parameter's online.

In this example we have selected R88D servo drive.

Recommended Reading: How to Reduce Electro-Magnetic Interference in Servo Drives

Steps to Change Servo Drive Parameter Using Omron CX Drive

1. Start CX Drive software in your laptop. If you have installed CX-One software and all its component, then it will be under Omron -- CX-One -- CX-Drive

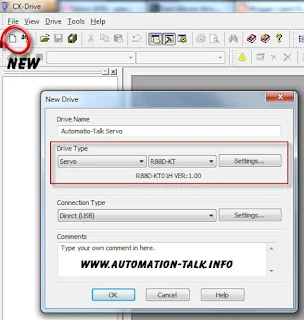

2. Now click on new and make your servo drive project. Here you will have to select a servo drive model from the list and you can also set the maximum rating of the drive through settings.

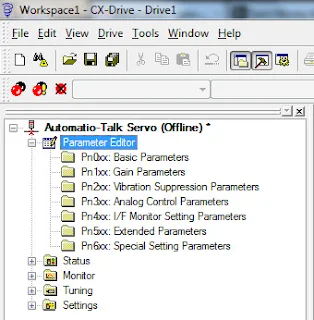

3. Now expand your new project and click on Parameter Editor. In parameter editor, you can even choose from different parameter list like basic parameters, gain parameters, vibration suppression parameter, analog control, special setting parameter etc.

4. Suppose we first want to set basic parameters, then just click on it and you will be shown all the basic parameters of the servo drive.

Now suppose we want to change control mode of the drive, then we can use parameter Pn001 and can set its value as required for the project. See the example below.

Similarly, you can change any parameter of servo easily.

Now to transfer this new setting to your drive, just go to transfer, which is under drive tab and transfer the settings to your drive. And if you are not connected to your drive you can also save your setting for after use. I like this method because you can use the same settings for every drive and you can save your project parameter wise, which saves your precious time.

If you like our articles, please consider them sharing with your friends and do like us on Facebook. You can also share your views and feedback through comments.

Dec 14, 2018

How to Change Servo Drive Parameter using Omron CX Drive

Jul 23, 2018

Advantages/Benefits of Servo Motor Over Induction Motor

We have discussed about the servo basics and servo control terminology in the previous article. We have studied about the different components of a servo control. Today in this post we will see that what are the advantages that we get by using the servo motor over the AC Induction motor. This article is in continuation to the previous one and here we will learn more about servo control.

Servo Motor V/S AC Induction Motor

Let us, first of all, see that what are the advantages of using the servo motor. Why it is that Servo Motor gives better efficiency for many applications. Suppose that an Induction motor is connected to run a grinder at full speed, we can expect to get some level of performance in this case. But is same grinder is run through Servo Motor we will get the next level of performance. So how it is achieved? Let us discuss in detail.

As we have discussed in the previous post that a servo motor is always used with a control and feedback device. The servo control issues the command for the position and the feedback device monitors the load and inform the servo control so that the control can correct the position if there is any error.

Advantages of Servo Motor Over Induction Motor

1. Increased Performance:- A servo motor has got more acceleration rate and higher speed capabilities compared to the induction motor and thus allowing the enhancing the production rate of the machine.

2. Smaller Size:- Servo motor has the higher output torque rating for the same size of the rotor. Thus Servo motor can be installed in a place where space is of prime concern.

3. Less Weight:- Weight of the Induction Motor is more than the servo motor for the same rating.

4. Highly Efficient:- A servo motor is designed in such a way to have peak efficiency and thus a better power conversion factor and thus saving the power.

5. Quick Positioning:- Servo motor can be issued a command to move accurately to the desired position in very less time, this is not possible with Induction motor.

6. High Degree of Accuracy:- In critical applications where we need the accuracy in microns or mm, the servo motor can provide it as it is designed for highly precise positioning.

7. Control-ability:- Last but not the least, as the servo control is used along with the servo motor thus a full control is achieved over the servo motor.

Also, one major point to be noted here is that the power of servo motor is utilized only when a position move command is issued to servo motor and rest of the times servo motor is normally turned off, thus a large amount of power is saved.

We hope that after reading this article about the advantages of servo motors over induction motor, we have come one step ahead. In the next article, we will discuss about the Permanent magnet DC Motor and AC Brushless Motor, till then you can subscribe to Automation-Talk by Email to get all latest updates.

Oct 30, 2017

How To Reduce Electromagnetic Interference in Servo Drives

Motion Controllers and Servo drives are used in machines for the better controlling and accurate positioning purpose. The one thing which we should keep in mind while installing the motion control panel is to have a safe and healthy environment for the Servo Drive and Motor operation i.e the environment should be free from any Electromagnetic Interference (EMI). EMI can dramatically reduce the performance of the system and can lead to various other problems. In this post, we will see that what practices should be followed in order to have the minimum or zero effect of EMI.

Reducing EMI effect by following Standard Wiring Practices

Generally, all major servo drive and motor manufacturers have their products following CE compliance. But using CE approved components will not guarantee a CE compliant System. The whole depends upon the components In drive, interconnection procedure, and installation method. So we should follow the practices by which the EMI effect can be minimized.

Electromagnetic Interference is generally generated by High frequency switching circuit. EMI generated inside the enclosure is either conducted or radiated back inside the enclosure only, so proper measures should be taken in order to avoid EMI conducted back into the main power source. Below picture illustrates that how EMI is conducted or Radiated back to the main power source.

Steps to Follow for Reducing/Minimizing Conducted EMI Effect

In order to reduce the Conducted High-Frequency noise, an EMI filter should be installed in series with the power supply. This EMI filter should block frequencies causing Interference and also not saturates at the current level required for normal operation. The EMI filter should be installed in such a way that it blocks EMI conduction to main power supply.

Shielded and Screened cables should be used wherever appropriate. Power Supply cables should be kept separate from Signal Cables and all cables should be as short as possible. Ground wires should have sufficient cross-section area in order to minimize the Skin Effect and conduct EMI to ground. Connect the EMI filter properly as shown below.

How to Remove the Radiated EMI Interference:-

Several points should be kept in mind to reduce the radiation of EMI back to the main power source. If there are any holes in the enclosure than the Holes should be as small as possible. Use conducting Gasket at seams of the door. Avoid grounding the Screens/Shield at only one end, doing this can dramatically increase the radiated EMI. If you found any particular cable is creating much EMI than it can be reduced by ferrite beads.

We will summarize the important points below:-

All cables that connect to motor control should be shielded. Input power cable and Motor Output cable should be separate and positioned independently. Grounding must be done properly and all cables should be laid close to the ground plane. The motor cable shield should be connected to a motor ground terminal at motor side.

The above picture shows the standard wiring procedure for better efficiency.

The shield/screen of all cables connected to the control must be grounded to the control by connecting the shield to the control’s “Ground” terminal. The cables include the motor cable, input cables, feedback cables regen/dynamic resistor cables and other control cables.Subscribe to Automation-Talk by Email.

If you strictly follow all the steps told above, then definitely the EMI effect will be minimized and will achieve better efficiency and increased life of your product. In upcoming articles, we will further discuss the more advanced things to eliminate the EMI effect completely from your system. Till then you can subscribe to Automation-Talk by Email to get all latest updates by eMail.

Aug 11, 2013

How to Select Servo Motor for Projects using Free Tool

In industrial automation, proper selection of automation products is very important whether it is a PLC, sensor, motor, servo or any other component small or big., every one play a vital role. Improper selection of these component may lead to complete failure of the project. Therefore in this tutorial we will guide you, how can you choose best servo motor for your project using Omron Servo Motor selection free tool. Subscribe to Automation-Talk by Email.

I still remember my early project days, where one of colleague choose wrong Induction motor and due to which client sheet laminating project become complete disaster. The motor he choose was under rating due to which machine was stopping due to overload. So don't repeat such mistakes and always choose correct rating motor.

This was the case of general induction motor and same can happen in servo project too, so proper selection of servo motor is must to get precise output.

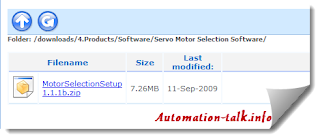

If you work on Omron products, then you can use a servo motor selection tool from Omron which is freely available at MyOmron.com at below path. It is just a 7.26 MB application and does not require more space and memory.

Folder path : /downloads/4.Products/Software/Servo Motor Selection Software/

This tool is very unique and useful and lets you select servo motor based on your project requirement. Suppose you want to make a project where servo motor is required at conveyor belt, roll feeder, suspension, ballscrew etc., then this is the tool for you.

Recommended Article : Best PLC programming Books

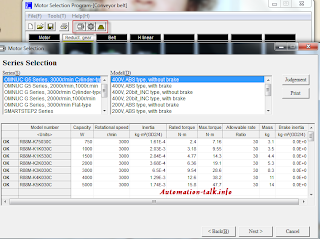

When you start Servo motor selection tool, you have to choose the purpose of your servo motor. Let say we need servo motor for conveyor belt system, then we choose the same as shown below.

After selecting your mechanical system, this tool will ask information about your components and your requirement. Like in conveyor belt it ask for reduct gear, belt & H linear values. We are keeping these setting as default for demo purpose, you can edit it as per your needs.

Recommended Article: Understanding Servo & Motion Basic

Now the next step which you have to perform is that, you will have to put your operating value. Let say I want 1500 rotation per min in 2 second interval, just fill 1500 in RPM section and 2 seconds in time section, rest is automatically calculated.

Now after entering your requirement you can click on Motor selecting icon which will show you recommended servo motor names form Omron. Now you can choose one which best suits you as per your capacity, RPM, Torque etc. requirement. You can click on judgement to see if you are selecting right servo or not.

Now just click on next button after selecting your motor and print the report and send to your client or save to your project file. A sample servo motor selection report can be downloaded from this link.

Hope you found this article useful and will use to select your servo motor too. Let us also know what you think about this tool with your comments and feedback. Do stay in touch and join us at Facebook and Twitter.

Dec 16, 2012

Troubleshooting the Baldor Servo Drives - Basic Things to Remember

We have discussed in detail about the Baldor servo drives earlier and also a full learning series on Mint workbench. Generally, we face a lot of problems in troubleshooting the servo drives. In this post, we are going to discuss some of the useful points which we should keep in our mind while working with Baldor servo drives.

Troubleshooting Common Problems of Baldor Servo Drives

Well, there can be many problems while working with servo drives, so we have divided this post into 5 different sections according to the type of problems.

1. Solving Serial Communication Problem in Servo Drives

*Check the controller has logic power supplied. The Status display should be active and the internal fans operating (on some units fans do not operate until the controller is enabled). The controller must have a logic supply connected to enable communication over the serial port. The logic supply is connected at X1, or internally generated from the AC supply (depending upon model).

* Try power-cycling the controller. This will reset the controller's serial drivers and may allow communication.

* Check the controller is properly earthed/grounded

* Try an alternative serial cable and/or confirm that it can be used to establish communication with another Baldor controller.

* Confirm that the PC's serial port is operating correctly

2. Drive enable problems - Drive is not enabled

*On FlexDriveII, Flex+DriveII or MintDriveII, confirm that front panel DIP switch 8 (enable) is set to the ‘On’ position to allow the drive to be enabled. To check that the firmware can detect the operation of this switch, check the Spy window's Axis tab where the state of the enable DIP switch is displayed. Alternatively, use the Command window to check the value of ENABLESWITCH.

*On FlexDriveII, Flex+DriveII or MintDriveII, check the setting of DRIVEENABLEMODE. Unless mode 1 or 2 has been selected, it will be necessary to enable the controller using DRIVEENABLE.

*Check the drive enable input is correctly wired and +24VDC is present.

*Check that there are no initialization errors which may be preventing the drive from being enabled.

Recommended Article: PLC Programming For Counting Encoder Pulses

3. Drive error Problems

* DRIVEERROR bit 0 (Powerbase fault) or bit 1 (Coprocessor) is reported.

This error indicates that the DSP processor has detected an interprocessor communications fault; this should not occur. If the problem persists, contact Baldor Technical Support.

* DRIVEERROR bit 2 (Current fault) or DRIVEERROR bit 3 (Overspeed) is reported.

If this error occurs when using a resolver motor, check the feedback cable. If the cable is not connected or there is an intermittent signal, the motor will run in an uncontrolled manner and cause an over speed or overcurrent trip. If this error occurs during a high acceleration motion profile, check the setting of DRIVESPEEDFATAL, the over speed trip value.

Use the Monitor tab and Scope mode to capture the move profile and establish what sort of overshoot is occurring on measured speed. Overshoot is typically the result of inappropriate gain terms or a high acceleration profile.

4. INITWARNING problems in Baldor drives :-

* INITWARNING bit 0 (Non-volatile RAM invalid) is reported. The contents (one or more elements) of NVRAM is corrupt. Use NVLONG and/or NVFLOAT to establish which element is corrupt, then write a new value back to those elements or reset the entire array using NVRAMDEFAULT.

* INITWARNING bit 1 (unknown PLD version) is reported.

5. Miscellaneous problems of Servo Drives :-

Well, there can be situations that you are facing some problem which we have not discussed above and you are not able to solve it. So it may also happen but never give your hope. A good PLC engineer should try his level best until the issue is resolved.

If still there is the problem in the servo drive then check the below points.

Use the Monitor tab and Scope mode to capture the Measured Velocity, Demand Velocity, Effort and Drive Bus Volts during the move profile. If the move is a MOVEA or MOVER command, and the plot of Demand Velocity is a triangular shape, the length of the move is not sufficient to reach the slew speed (SPEED) using the current settings of ACCEL and DECEL. Increase ACCEL and DECEL to allow the move to reach the intended slew speed. A longer move will also be more likely to reach the slew speed.

If the plots show that Demand Velocity reaches DRIVESPEEDMAX, but Measured Velocity does not inspect the plots of Effort and Drive Bus Volts.

We are sure that after reading you must have increased your knowledge base about the servo drives. Keep visiting for more updates and don't forget to like us on Facebook. Subscribe to Automation-Talk by Email.

Nov 21, 2011

Difference Between PMDC and Brushless Servo Motor

In our earlier two articles we have discussed about the Servo and Motion basics and also the advantages of Servo Motors. Today in this post we will see the two different type of Servo Motor and the differences between them. PMDC (Permanent Magnet DC) Servo Motor and Brush less Servo motor are two different types of servo motor which differ in their construction and the commutation method.

PMDC Servo Motor Simple Explanation/Construction and Working :-

PMDC Motor consists of Stator which has Permanent magnet i.e stator field is produced by permanent magnets. The stator field is stationery. The rotor field is produced by passing current through the rotor and commutator assembly. When current is supplied, a field is generated inside rotor and it rotates to align itself with the stator field but the commutator switches the rotor field and thus the rotor field never catches up the stator field. The speed of the rotor will be dependent on the Rotor field which in turn is dependent on the voltage supplied to it. The stator field is produced by permanent magnets and is constant at all speeds.PMDC Servo motor has high starting torque and acceleration torque. Also it has smaller frame size and less weight as compared to the brush less servo motor. Below is the diagram of the construction of PMDC servo motor.

AC Brush less servo Motor Construction and Simple Working explanation :-

In AC brush less servo motor the method of commutation is different as compared to PMDC Servo Motor. The power is supplied to the stator windings and thus a field is setup. The rotor field is set up by the permanent magnet. The rotor field rotates itself in order to align with the stator field but as soon as it is nearer to align , the polarity changes at stator side and thus the field and then again rotor keeps on rotating itself to align with the stator field. Thus with the electronic commutation the power is switched from winding to winding and rotor rotation is achieved. AC brush less motor have higher speed capabilities and lower inertia , so suitable for faster and accurate positioning applications.

See the below diagram for the complete constructional view of the AC Brush less Servo motor.

Till now in our three artciles we have discussed the basics and different types of Servo and Motion. In further articles we will try to discuss advanced information on Servo and Motion. If you have any specific query related to Servo's , you can write to us in the comment section.

Subscribe to Automation-Talk by Email.

Oct 20, 2011

Understanding the Servo & Motion Basics

Servo systems are used widely to control the position and velocity or torque of the load.Accurate and Precise motion of machines is achieved with the help of servo systems. We have already discussed about the Servo Fundamentals in our earlier post. Today we will try to understand the fundamentals of Servo and Motion control for the beginners. First of all we should understand that what do we mean by a Servo System? What a Servo System consists of and What functionality it gives , these will be the questions which we will be discussing in this post.

Basic Fundamental of Servo Control and Motion :-

A Servo system consists of a Servo drive and Servo Motor. These systems are used where precise positional move is required,where there is frequent starting and stopping and also where there is very frequent change in direction of motion. Servo Motion has gained the attention from all over the world because of its frequent precise movement capabilities.Servo Control is a closed loop system , where there is feedback form the load side to the controller about the present condition.

A servo responds to the feedback signal in few milliseconds and the desired correction is done. Servo Control generally used for Velocity and Position control. But in majority of applications both the control are needed. There are applications where it is desired that the positional move should occur within a time frame for increased productivity , so in all such applications both velocity and position control are needed. Industries demanding such application include textile, medical and packaging.

Servo Control Terminology and Parts of Servo Motion System :-

Servo Motor - It is the section of servo control which drives the load or it provides motion to load. Servo Motor may be connected via Gearbox with load. The Servo Motor have very fast response and usually low inertia.

Servo Control - It is the part of system which controls the amount of voltage and current given to motor i.e it controls the amount of power supplied to the motor. The amount of power supplied to motor decides the motion i.e if more voltage given then motor moves fast and so on. The servo control moves the motor to a specific position with desired speed and continuously monitors the feedback signal to monitor that desired motion is achieved or not , if not then it changes the signal to correct it and all these things happen in a matter of milliseconds.

Feedback - A feedback device (encoder, resolver)is located inside the motor and gives signal to servo control about the current position speed etc .

Power Supply - It is used to convert the AC Supply to DC Supply.

Motion Controller for Accurate Positioning :-

The servo Drive only controls the speed or velocity of motor. SO we need a controller which issue the command for the movement , so a controller is needed and this controller is programmable and we can program it according to our application requirement. See the Below block diagram for a better understanding.

A Motion controller is the heart of the system , i.e it monitors the position and issue accurate commands for the desired motion to take place. User can program it according to application demand and moreover we can have multiple servo control with the single controller. User interface can be a PC or HMI.

We hope that after reading this article you must be familiar with the servo basics and in further articles we will discuss more about the Servo and Motion , till then you can subscribe to get all latest updates.

If you have any doubts then you can contact us through the comment section.

Subscribe to Automation-Talk by Email.

Mar 15, 2011

Baldor Servo Drive Auto-Tuning/Installation Procedure

Baldor Electric is a well known name in Servo Motor and Drives. There are four major series of servo drives by Baldor namely as Flex , Flex + , Micro Flex and Mint Drive. All Baldor Servo Drives can be Auto-Tuned by the Programming software called as Workbench. Through this Software you can easily Auto-Tune and adjust gain and other parameters of Servo Drive according to the application.

How to Install Baldor Flex/Micro Flex Servo Drive :-

First of all make proper power connections at Servo Drive side. Connect the Motor U V W wires at correct terminals. Also connect properly the Encoder Cable , there should not be any loose connections and dry soldering in Servo Drive Encoder cable. Also make sure that Motor power and Encoder Cable shield is connected to ground at one side.

How to Auto-Tune the Baldor Flex/Microflex Servo Drive:-

Now after making the proper connections , we are ready to Auto-Tune the servo Drive. First of all install the Workbench Software. Every Servo-Drive comes with a CD and this Software is there in CD. After Installing the Software you will Need the Programming Cable. We already posted about the Programming Cable Connection Details.

Connect the Programming Cable and open Workbench Software. Note down two things earlier that what is the maximum RPM and PPR of encoder. After opening the Workbench Software , click on start a new project.After this a window will open and you can scan the connected servo drive. ( Note :- Make sure that cable is connected and drive is powered up). The software will automatically detect the Connect servo Drive.

After that you will see the controller found , select this and click on Select. After this the commissioning Wizard will open automatically , here in the first step select the type of Servo Motor connected with servo drive i.e whether the servo motor is Rotary Brush less or linear brush less type. Then Click Next and in this window Write the Model Number of the Servo Motor connected with Servo Drive. After this we have to define the Operating Mode of Servo Drive i.e Speed , Position or Current Mode.

After this the Auto-Tune window will open up , generally first of all OFF-Load auto tuning is done , so make sure that servo motor is not coupled with load. And first start Auto-tuning off-load. When the Off-load Auto-tuning is over , check the box at the top right side and perform on load auto-tuning. Make sure that Servo Motor Shaft is coupled with Load when doing On Load Auto-Tuning.

Now the Servo Motor is Tuned according to the Motor Parameters. If you see at the left side in Workbench Software , then there is Parameters Tab , here you can adjust the Analog Input

offset.

Also for testing purpose you can Jog the servo motor in both the directions and at your rated speed.

Also if explore out the Workbench Software then there are many other advanced features and you can adjust the gain and many other parameters according to yours application. We will be discussing more about the advanced features in our next post , till then you can subscribe to get all updates in yours Inbox.

Subscribe to Automation-Talk by Email.

Feb 27, 2011

Servo Motor Basics - Closed Loop System

Servo has been a Key Solutions for Applications demanding high accurate and fast positioning closed loop feedback systems. What makes Servo so special? What is there in Servo Motors which cant be done by AC Induction Motors? We will see in this post the functioning of servo motor.

Servo Controller Fundamentals :-

Servo Controller has made possible to reduce the transient response time along with reducing the steady state errors. Better the Transient response time the more is the System bandwidth and thus allowing for faster response and better machine throughput. Less Steady state errors directly indicates for better accuracy.

Below you can see the basic block diagram of servo-mechanism. AC power supplied to Servo System is divided in to two levels as Low and High Level internally by controller electronics section. The low level power is given to Servo Amplifier , which in turn amplifies or increases this signal for motion of servo motor or load.

The low level signals must be amplified as higher voltage is required to rotate the Servo Motor at higher speeds and more current is required for Heavier loads demanding more torque. As we know that Servo System is closed loop System , so when Servo Motor Moves , encoder attached with it also moves and the feedback is received by Controller/Servo Amplifier.

The Servo Controller then looks at this Feedback by Encoder to decide whether the Load is moving properly or not. Suppose for example a command is issued for 5000mm movement of Load and feedback is received for only 4500mm , so controller will issue a command for another 500mm movement. So this is closed loop system and process continues on.

The controller always monitors the Command Signal Issued and the Feedback Signal , they both have t be matched for 100 percent accuracy and zero error. The Command Signal and feedback Signal are compared regularly and corrections are made. So servo is not a single device rather it is a collection of several devices.

We will be discussing more about servo basics and facts , till then you can subscribe to get all updates directly to your mail-box. Subscribe to Automation-Talk by Email.

Feb 15, 2011

Omron SmartStep Servo User & Operation Manual

SmartStep is the Servo system series from Omron and comes with many features. The servo Package comes in different different rated output from 100W to 750W in Flat Servo Motor and from 30W to 750W Cylindrical servo motors. This servo Package name start from R7 and Servo Drive Nomenclature start from R7D and Servo Motor Nomenclature start from R7M. Subscribe to Automation-Talk by Email.

SmartStep is the Servo system series from Omron and comes with many features. The servo Package comes in different different rated output from 100W to 750W in Flat Servo Motor and from 30W to 750W Cylindrical servo motors. This servo Package name start from R7 and Servo Drive Nomenclature start from R7D and Servo Motor Nomenclature start from R7M. Subscribe to Automation-Talk by Email.

The SmartStep motors offer the simplicity and cost-effectiveness of a stepper with the added advantages of a servo system. It is available in many Sizes like 30W to 800W, rated speed 3,000 rpm.

You can see the below links for Manual of Omron SmartStep Servo

SmartStep Users Manual

SmartStep Operation Manual

Source: Omron UK

These manuals are in English for other language you can make a request.

Jan 2, 2011

I/O Connection and PLC Program for Omron Servo Drive to Run Through PLC

Omron Servo Drive R7D-AP08H can be interfaced with PLC to run the Servo Motor in Controlled manner and as per our applications and need. PLC will provide pulses to Servo Drive and accordingly servo motor will run. We just have to make some hardware connection and write a suitable correct program in PLC. We will see the step by step procedure here.

One thing we should keep in mind that our PLC should have pulse type output, then only it can provide pulses to the servo drive.

Connection Diagram OF Omron Servo Drive R7D with Omron PLC CP1E/CP1H

First of all, we have to make the control connections between our servo drive and PLC. If you Look at the front of servo drive then there is R7D-AD I/O connector, we have to connect some terminals of it with PLC. It is a 20 terminal connector but for our purpose, only 6 terminal connections have to be done.

Recommended Article: Understanding Difference Between Source & Sink in PLC's

See below details for Interfacing of Servo Drive with PLC. Subscribe to PLC, HMI Programming and SCADA Tutorials by Email .

Here we have considered the PLC as output as T1 type i.e PNP transistorized output.

PLC SIde--------------------------------------------------------------Servo Drive(AD I/O)

100.0 --------------------------------------------------------------- terminal 1 (+CW)

100.1 --------------------------------------------------------------- terminal 3 (+CCW)

N24 V --------------------------------------------------------------- terminal 4 (-CCW)

N24 V --------------------------------------------------------------- terminal 2 (-CCW)

NOTE:- N24 V stands for 0V or negative 24 v DC.

Connect the Common of PLC to P24 V.

You can see the Below picture for a better understanding.

Note:- Click on the picture for a clear view.

So our half part is done now we have to write the PLC program to provide the pulses to the servo drive.

PLC Program for Servo Drive to Run Through PLC

Here we are using output 100.0 and 100.1 as depicted above in connection diagram to give pulses to the servo drive. So we have to configure the output as pulse type in our program.

We have to write PULS instruction to specify the port and a type of Pulses i.e relative or absolute and also number of Pulses. Then we have to write SPED instruction to specify the mode that is the motor should run in clockwise or anti-clock wise direction and also the frequency of pulses i.e the RPM/speed of the motor.

With the Help of PULS and SPED instructions we can make any combination to run the motor as per our requirement. Generally, we have defined the number of pulses in PULS instruction, 1000 pulses are required for 1 rotation and we have to define the speed in SPED instruction.

We have made a PLC Program for yours better understanding and examples of both CW and CCW is given in the PLC Program. You can download it from below link.

Download Program

And after doing all this still if you are facing any problem then you can write in the comments section and we will be happy to help you. Don't forget to Subscribe to get all the servo related updates in your Inbox. Subscribe to Automation-Talk by Email.