Today competition is in every field has increased a lot and to be different from other employees, we have to do different things. There are certification in every field and to get good recognition gaining certification is very important. Not only it increases competency but also gives professional recognition. So today in this post we have listed some industrial automation certification, which will help you in boosting your knowledge and career. Subscribe to Automation-Talk by Email.

4 Industrial Automation Certifications You Must Know

1. ControlLogix Certificate Program by Rockwell: Rockwell automation is a well know company in automation and their PLC's are used in every sector. So if you are a PLC programmer having experience in ControlLogix PLC's, then this certification is certainly for you. This is a self-preparatory program and you will have to follow the given syllabus.

You will complete a series of three required ControlLogix courses related to your maintenance or programming job responsibilities, plus one course elective.

To earn the ControlLogix certificate, the program requirements must be completed within 12 months. For more details please check here.

2. RSTrainer for RSLogix 5000 Software: This is another certification program by Rockwell which is a computer based training. To clear this certification you can get study material after registration and this course is available in both computer-based and web-based delivery formats and is part of a series of e-Learning courses designed to teach you RSLogix 5000 software.

Syllabus for this certification includes:

Introduction to RSLogix 5000 Software

• Installing RSLogix 5000 Software

• Identifying Main Window Components

• Configuring the Display

• Navigating through the Software

• Using Help Options

Creating and Configuring a New Project

• Creating and Managing Project Files

• Configuring a Controller

• Organizing Tasks, Programs, and Routines

• Configuring a Local I/O Module

• Organizing Data

• Producing and Consuming Tags

• Exporting and Importing Tags

Get more detail here

3. SITRAIN Certification Program: This is the certification program by Siemens and under this program, there are many certifications. This is a worldwide recognized program and the certification is valid for 3 years. Below chart shows the entry qualification for each certification.

The certifications are divided as per PLC make and model viz. Certification based on SIMATIC S7-300/-400 with STEP 7 V5.x and Certification based on SIMATIC S7-1500 with TIA Portal and there are some compulsory training which you must attend before attending these certifications. There are also certifications in the Process Automation field. Get more information here.

4. Professional Certificate of Competency in Programmable Logic Controllers (PLCs) & SCADA Systems: This certification is from Engineering Institute of Technology (EIT) which is endorsed by the International Society of Automation (ISA). This is a general purpose certification course for new learners and include basic concept of SCADA and PLC system, PLC programming (ladder logic), industrial communication protocols, PLC panel designing and much more.

Syllabus, fees and more information can be found here.

Apart from this certifications, there are many local institutes which gives you the PLC programming and SCADA training at low cost. In this program they teach about 2-3 different make PLC, SCADA, PLC programming, Electrical etc. If you know any other industry wide automation certification, please let us know through your comments.

Feb 18, 2019

4 Industrial Automation Certifications You Must Know

Oct 18, 2013

LabView and PLC communication through OPC Server

As we all know that LabView is a software which is used for designing and development environment for a visual programming language and is from National Instruments. LabView has found its use in many places and many of the engineers are making their design on LabView. In Automation industry we use different-different devices and software to implement or projects and OPC server (OLE for Process Control) is one such very useful software or protocol which is widely used. In this tutorial we will guide you how you can communicate LabView and PLC through an OPC server. Subscribe to Automation-Talk by Email.

Tutorial Requirements:

1. PLC [we are using Allen Bradley Micrologix 1000 PLC here]

2. LabView 2012

3. OPC server [Kepware]

4. Communication cables.

Let me tell you that we can use LabVIEW as an OPC client by connecting to an OPC server through a DataSocket connection and we done same and communicated OPC server and LabView through DataSocket VI. In this tutorial we are using Kepware OPC server for communication.

The DataSocket palette in LabVIEW:

Below is the picture of DataSocket palette in LabView which shows you different buttons for performing different task as explained below.

DataSocket Display URL: Displays a dialog box for the user to select a data source and returns the URL to that data.

DataSocket Open: Opens a data connection you specify in URL.

DataSocket Read: De queues the next available data value from the client-side buffer associated with the connection you specify in connection in and returns the data.

DataSocket Write: Writes data to the connection you specify in connection in.

DataSocket Close: Closes a data connection you specify in connection id.

LabView and PLC communication through OPC Server

Now lets start with communicating PLC and LabView through Kepware OPC server. OPC has some standard URL format which looks like opc://machine_name/server_name/item_name.

Here in following we use KEPware.KEPServerEx.V4 OPC Server and channel name is a; device name is b; and tag name is t0. So; OPC URL is as following;

opc:/KEPware.KEPServerEx.V4/a.b.t0?updaterate=100

If you know URL in advance, then you can directly use that URL with DATASOCKET OPEN VI. This VI opens a data connection we specify in the input URL as below.

Read OPC Data

Use DataSocket Read in order to get data from a specific Item in the OPC server as below.

We can also read by using URL directly like below.

WRITE in to OPC Data

You can use DataSocket Write in order to write data to a specific Item in the OPC server. In order to write data to an OPC Item it must have the Write property set.

We can also write using the specific URL directly like this:

Now after making all the setting you can test your PLC and LabView, below is the video of same. You can write a simple ON-OFF program for PLC.

This communication is done by one of our Facebook Fan page Vijaysinh Rahevar and we are very thankful to him. If you also want to submit your tutorial, just get in touch with us on Facebook.

Oct 1, 2011

Micrologix 1000 Tutorial Explaining AND & OR Function

Here is a very good video tutorial from BTC Instrumentation for beginners, who want to understand the concept of AND and OR function in a PLC. In this tutorial Allen Bradley MicroLogix 1000 PLC is used and both the function are explained with proper live demonstration. The video is easy to understand and will clear your doubts. Subscribe to Automation-Talk by Email.

Jun 17, 2011

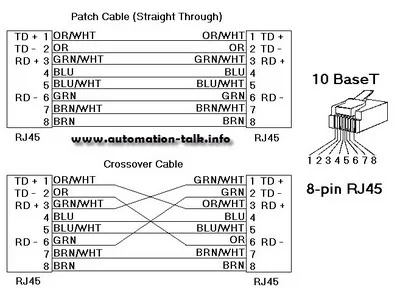

Allen Bradley Ethernet Cable Connections

If you are setting an Ethernet Connection for Allen Bradley PLC like SLC5/05 series and PLC5 you will first will require an Ethernet Cable for Connections.

Jun 16, 2011

Allen Bradley SoftLogix5800 System User Manual

SoftLogix5800 comes under large PLC system of Allen Bradley and used as a common control engine with a common development environment to provide high performance in an easy-to-use environment. This manual will provide you the information of Catalog Numbers 1789-L10, 1789-L30, 1789-L60. This manual will tell you about SoftLogix5800 Controller Installation Instructions, Instruction Execution, Connections for Produced and Consumed Tags, Configure Your System for a DeviceNet Network and its troubleshooting and lot more. Subscribe to Automation-Talk by Email.

Download Allen Bradley SoftLogix5800 System User Manual

Jun 14, 2011

Matrikon OPC Server For Allen Bradley PLC

OLE Process control or OPC are still the major way for connecting different tags of your SCADA application, HMI or any other application which uses OPC to your PLC. If you are using Allen Bradley PLC's like PLC5, SLC500, Micrologix, and Control Logix then Matrikon OPC Server can be a good option for you to connect the PLC using OPC. This Allen Bradley OPC Server securely communicates over Ethernet, Serial, and "Blue Hose" to many Allen Bradley protocols such as: DF1, DH+ (Data Highway Plus),DH485, Ethernet/IP (Allen Bradley CIP). This is a very advance OPC server for Allen Bradley PLC which can grant and deny access to tags based on user login and is a useful security feature. Subscribe to Automation-Talk by Email.

You can download this Allen Bradley OPC server which is demo from below link. You may have to register to download OPC server for Allen Bradley PLC's.

Download Demo Matrikon OPC Server For Allen Bradley PLC

Feb 1, 2011

NV HMI Host Connection With Allen Bradley SLC ,MicroLogix PLC

NV HMI by Omron is capable of Host Connection with Many PLC's. In the earlier article we saw NV HMI Modbus Communication Set up Procedure. Now in this article we will discuss the NV HMI Host Connection Procedure with Allen Bradley Range of PLC.

NV HMI Host Connection With Allen Bradley SLC and Micrologix 1000 :-

First of let us see the Cable Connection Diagram for Connecting Cable Between SLC - 5/03, 5/04 and NV HMI for Rs232 communication. There is D type Connector at PLC side and 8 terminals at HMI side.

PLC D Type Connector-----------------------------------------------------NV HMI

Pin 2 (RD)--------------------------------------------------------------------Terminal 4 (SD)

Pin 3 (SD)--------------------------------------------------------------------Terminal 5 (RD)

Pin 5 (SG)--------------------------------------------------------------------Terminal 8 (FG)

Note :- Short the Pin 7 and 8 at PLC Side D type Connector , also short Pin6 and Pin4 with Pin 1 at the PLC side.

Make the Connecting Cable as shown above for connection of NV HMI with Allen Bradley SLC -5/03.

Communication Cable Diagram for AB MicroLogix 1000 with NV HMI Omron :-

MicroLogix PLC by Allen Bradley has Round Type RS232 Port , Make the Connecting Cable accordingly as shown Below for RS232 Communication :-

PLC Round RS232 ---------------------------------------------------------NV HMI

Pin 2 (SD)--------------------------------------------------------------------Terminal 5 (RD)

Pin 3 (RD)--------------------------------------------------------------------Terminal 4 (SD)

Pin 5 (SG)--------------------------------------------------------------------Terminal 8 (FG)

Make the Connecting cable for RS232C communication as shown above and connect accordingly at the PLC side and HMI side.

Now we have to make some settings in NV HMI software. NV Designer is used for making screens in NV HMI. Open the NV Designer Software and Create a New Project , Select the Proper Model of NV HMI which you are using and then in PLC Model Type select "Allen Bradley SLC-500 MicroLogix Series" and click next and select System Memory Area accordingly. See the below picture for a better understanding.

Note :- Click on the Picture for a Better Enlarged View.

After Selecting the Proper PLC Model as told above , we have to make some communication parameter settings. In the NV Designer Software click on PT --- NV Configuration and then here Under Communication Parameter Tab select NV Unit Number as 1, PLC unit Number as 0 and Baud Rate as 19,200 , Data Bit 8 , Parity - None and Stop Bit as 1. See the below picture for a better understanding.

Note :- Click on the Picture for a Better Enlarged View.

Now we are done with settings in NV designer , now you can make the Screens as per your application.

Settings in RSLogix for RS232 Communication with NV HMI :-

Now we have to make some simple Communication Parameters setting at PLC side also as we did in NV Designer for HMI. Make the following Communication parameter settings .

Baud Rate -19,200 bps , Parity - None ,Stop Bits -1 , Data Bits - 8, Communication Driver - DF1 Full Duplex , Control Line - No Handshaking, Error Detection - CRC , Embedded Responses - Enabled , Duplicate Packet Detect - Enable.

Now we are done with all the necessary settings to be done for RS232 Communication between Omron NV HMI and AB SLC MicrLogix series PLC.

You can make HMI screens as per your application and assign any Bit Address as per your need, you will be able to access all PLC Bits and Integer values through HMI now. Keep in Mind to make the Communication Cable properly.

Also You can subscribe to get all related PLC programming,HMI Updates in yours Inbox.

Subscribe to Automation-Talk by Email.

Jan 29, 2011

Network Types In Allen Bradley PLC

There are different types of Network in PLC used for connecting the external devices and connecting with other PLC to form a Network. Here in this post we will see the brief overview of common types of Network in Allen Bradley PLC. Networking in PLC is used in high end applications and we should be aware of different types of Networks.

Network Types In Allen Bradley PLC | Networking in Allen Bradley PLC :-

[1] RS232 Based DF1 Network :- RS232 port is present in almost all controller manufactured by Allen Bradley for programming Purpose. We can use RS232 Port for communication with SCADA and HMI

a) Driver Used - AB_DF1

b) Maximum Number of Node - 2

c) Maximum Speed/Baud Rate - 19.2Kbps

d) Maximum Cable Length - 15 Meters.

[2] RS-485 based DH485 Network :- DH485 is an Industrial LAN used for factory floor applications . The advantage of this network is that we can program all the controllers in the network using a single work station.

Note :- RS232 link along with RS485 make a DH-485 network.

DH485 is a very slow network , it should be used for non-critical processes as it gives much delay in communication. To Configure the DH485 Network we need AIC+ i.e Advance Interface Converter.

AIC :- Advanced Interface Converter has 1 D type RS232 Port and 1 round type RS232 Port and one 1 RS485 port. RS 485 port is used to link one AIC with another to form the network , while the RS232 port is used to connect the external devices.

a) Driver Used - 1747 PIC/AIC +

b) Maximum Number of Node - 32

c) Maximum Speed - 19.2Kbps

d) Maximum Length - 1200 Meters.

[3]Ethernet Network :- In this type of Network the data is transferred in the form of Packets. It is the most widely used LAN topology. It was originally developed by XEROX corporation of USA , and based upon CSMA/CD.

What does CSMA/CD means ? CSMA/CD stands for Carrier Sense Multiple Access and Collision Detection. Every PLC in this network has its own unique IP address.

PLC IP address consist of Net ID and Host ID. The IP Address configuration is of class C i.e there are there 3 Net ID and 1 Host ID.

Driver Used :- Ethernet/Ip

Baud Rate :- 10-100Mbps.

[4] Device Net Network in Allen Bradley PLC :- It is simple Open Networking solution, here open networking means that we can have other make PLC also in the Network. It reduces cost and time required to wire and install Industrial Automation devices which provide interchangeability of like components from Multiple Vendors. The base of this network is CAN i.e Control Area Network Technology. It is an effective way of exercising intelligence present in the filed instruments as it avoids hard wiring of each I/O in to the Controller(PLC) individually.

a) Maximum Node in Device Net Network :- 64

b) Maximum Baud Rate :- 500Kbps

c) maximum Length :- 487 Meters.

[5] Control Net Network in Allen Bradley PLC :- It is a Real time control network which provide high speed transport for messaging data , interlocking data and communication data including upload and download of program using physical media link.

Rockwell Automation Offers a complete range of Control Net supported products including Controllers (PLC) , HMI , Motion Control , Motor Control Devices , I/O's , Media and Software Drivers.

a) Maximum Node in Control Net Network:- 99

b) Maximum Baud Rate :- 5Mbps

c) Maximum Length :- 30Km.

For such More PLC Networks information , subscribe to get all updates in Yours Mail.

Subscribe to Automation-Talk by Email.

Jan 19, 2011

Allen Bradley PLC Types Presentation

Allen Bradley is one of the most used PLC brand in Automation Industry and has cover a half of the market. In this presentation on Allen Bradley you can see types of PLC in Allen Bradley like Micro, SLC, Compact Logix etc. This presentation also tells about the design of CPU of Allen Bradley PLC's and also how to connect Allen Bradley PLC and Wiring diagram of these PLC's. Subscribe to Automation-Talk by Email.

Download

Presentation On Allen Bradley PLC

Jan 16, 2011

How to Configure RSLinx With MicroLogix 1000 PLC

Micrologix Series is a widely used series of Allen Bradley in old times. Even now it is used widely in many industries. The MicroLogix 1000 is a programmable controller and available in 10-point, 16-point or 32-point digital I/O versions. Analog versions are also available with 20 digital I/O points, with 4 analog inputs (two voltage and two current) and 1 analog output. If you are having problem in connecting your Micrologix 1000 PLC then you can see this video. It shows you how to connect it with RSLinx. Subscribe to Automation-Talk by Email.

How to Configure RSLinx With MicroLogix 1000 PLC

Source:YouTube

Subscribe to Automation-Talk by Email.

Dec 19, 2010

Allen Bradley MicroLogix 1100 Reference Manual/ Selection Guide

Allen Bradley has a very popular PLC Series called MicroLogix which comes in the different series and are widely used PLC in the industries. This article gives you the Reference Manual/ Selection Guide of MicroLogix 1100 programmable controller, it contains a power supply, input and output circuits, a processor, an isolated combination RS-232/485 communication port, and an Ethernet port. Each controller supports 18 I/O points.Subscribe to PLC, SCADA, HMI Programming and Tutorials by Email.

Some Micrologix Catalog No. are 1763-L16AWA, 1763-L16BWA, 1763-L16BBB, 1763-L16DWD etc.Subscribe to Automation-Talk by Email .

Allen Bradley MicroLogix 1100 Reference Manual/ Selection Guide

MicroLogix 1100 Programmable Controllers User Manual

MicroLogix Selection Guide

Source:Rockwell Automation

Subscribe to Automation-Talk by Email For more Allen Bradley Manuals.

Dec 11, 2010

Allen Bradley MicroLogix 1000 Manual/ Selection Guide

Allen Bradley MicroLogix 1000 series provides small, economical programmable controllers. It has many benefits like Compact Size,Choice of communication networks, Comprehensive instruction set,Fast in speed. They are available in configurations of 10 digital I/O (6 inputs and 4 outputs), 16 digital I/O (10 inputs and 6 outputs), 25 I/O (12 digital inputs, 4 analog inputs, 8 digital outputs, and 1 analog output), or 32 digital I/O (20 inputs and 12 outputs) in multiple electrical configurations of digital I/O. The I/O options and electrical configurations make them ideal for many applications. Subscribe to Automation-Talk by Email.

It comes with many Communication port facility like Point-to-Point—RS-232, DH-485—RS-232, EtherNet/IP—RS-232 , DeviceNet—RS-232, DF1, half-duplex—RS-232. You can choose your PLC according to your Communication port requirement.

MicroLogix Programmable Controllers Selection Guide

MicroLogix 1000 User Manual

Source:www.ab.com

Subscribe to Automation-Talk by Email. for more Manuals.