Jan 11, 2024

3 Allen Bradley PLC Certifications & Courses

Jun 8, 2023

PLC Programming Languages

Introduction

What is a PLC?

Importance of PLC Programming Languages

5 Common PLC Programming Languages

Advantages and Disadvantages of Different PLC Programming Languages

Structured Text (ST)

Instruction List (IL)

Ladder Logic

Function Block Diagram (FBD)

Sequential Function Chart (SFC)

Choosing the Right PLC Programming Language

Application Requirements

Programmer's Skillset

Industry Standards

Conclusion

FAQs

Jun 1, 2023

How To Download Omron CX Programmer (CX-One) for Free

What is Omron CX Programmer?

How to Remove Omron PLC Password

Steps to Download Omron CX Programmer for Free

FAQs

Feb 21, 2023

20 Innovative Industrial Automation Projects to Improve Efficiency and Productivity

Industrial automation has become an increasingly popular way to improve efficiency, reduce costs, and enhance the safety of manufacturing processes. Automation can be applied to a wide range of applications, from managing the flow of raw materials to monitoring and controlling the speed of a production line.

20 Innovative Industrial Automation Projects

PLC Programming For Counting Encoder Pulses

Conclusion

Feb 18, 2019

4 Industrial Automation Certifications You Must Know

Today competition is in every field has increased a lot and to be different from other employees, we have to do different things. There are certification in every field and to get good recognition gaining certification is very important. Not only it increases competency but also gives professional recognition. So today in this post we have listed some industrial automation certification, which will help you in boosting your knowledge and career. Subscribe to Automation-Talk by Email.

4 Industrial Automation Certifications You Must Know

1. ControlLogix Certificate Program by Rockwell: Rockwell automation is a well know company in automation and their PLC's are used in every sector. So if you are a PLC programmer having experience in ControlLogix PLC's, then this certification is certainly for you. This is a self-preparatory program and you will have to follow the given syllabus.

You will complete a series of three required ControlLogix courses related to your maintenance or programming job responsibilities, plus one course elective.

To earn the ControlLogix certificate, the program requirements must be completed within 12 months. For more details please check here.

2. RSTrainer for RSLogix 5000 Software: This is another certification program by Rockwell which is a computer based training. To clear this certification you can get study material after registration and this course is available in both computer-based and web-based delivery formats and is part of a series of e-Learning courses designed to teach you RSLogix 5000 software.

Syllabus for this certification includes:

Introduction to RSLogix 5000 Software

• Installing RSLogix 5000 Software

• Identifying Main Window Components

• Configuring the Display

• Navigating through the Software

• Using Help Options

Creating and Configuring a New Project

• Creating and Managing Project Files

• Configuring a Controller

• Organizing Tasks, Programs, and Routines

• Configuring a Local I/O Module

• Organizing Data

• Producing and Consuming Tags

• Exporting and Importing Tags

Get more detail here

3. SITRAIN Certification Program: This is the certification program by Siemens and under this program, there are many certifications. This is a worldwide recognized program and the certification is valid for 3 years. Below chart shows the entry qualification for each certification.

The certifications are divided as per PLC make and model viz. Certification based on SIMATIC S7-300/-400 with STEP 7 V5.x and Certification based on SIMATIC S7-1500 with TIA Portal and there are some compulsory training which you must attend before attending these certifications. There are also certifications in the Process Automation field. Get more information here.

4. Professional Certificate of Competency in Programmable Logic Controllers (PLCs) & SCADA Systems: This certification is from Engineering Institute of Technology (EIT) which is endorsed by the International Society of Automation (ISA). This is a general purpose certification course for new learners and include basic concept of SCADA and PLC system, PLC programming (ladder logic), industrial communication protocols, PLC panel designing and much more.

Syllabus, fees and more information can be found here.

Apart from this certifications, there are many local institutes which gives you the PLC programming and SCADA training at low cost. In this program they teach about 2-3 different make PLC, SCADA, PLC programming, Electrical etc. If you know any other industry wide automation certification, please let us know through your comments.

Jan 24, 2019

Best Free PLC Simulator

While in a learning phase of ladder logic we usually don't have PLC programming software to test our logic made in paper or even you don't have a PLC software for your testing and reference. In that case, you can use some free PLC simulator which are available online. There is some site which provides students and trainer free PLC simulating software. Subscribe to Automation-Talk by Email.

Best Free PLC Simulator

1. LogixPro 500 PLC Simulator by TheLearningPit.com

LogixPro 500 is the ideal tool for learning the fundamentals of ladder logic programming. The full version of our LogixPro 500 Simulator is available for download and free evaluation. What this means is that you can download and try out LogixPro 500 in a 15 day Trial Evaluation mode, and make up your own mind as to whether it's the most advanced PLC Simulator and best training value on the market today.

Recommended Article: Best PLC Ladder Programming Books

2. TRiLOGI PLC Simulator software

TRiLOGI" is the name of the ladder or ladder + BASIC programming software for the Nano-10, FMD and F-series PLCs via LAN or the Internet. It can also be used for programming the legacy M-series (T100MD+ and T100MX+) PLCs, although some of features are not available to the legacy PLCs.

It is a perfect training tool for learning PLC programming. Students or technicians can quickly create a ladder logic program on their laptop and instantly test the program using the simulator. Do try it.

3.FREE Online PLC Simulator

plcsimulator.net provide free online PLC simulator. This PLC simulator will help you to enhance your PLC programming skills. Just visit the site and test your Ladder logic skills.

These were some of the best PLC simulator which are available online for FREE. If we find more such PLC simulator we will update your through our Email newsletter.

Dec 14, 2018

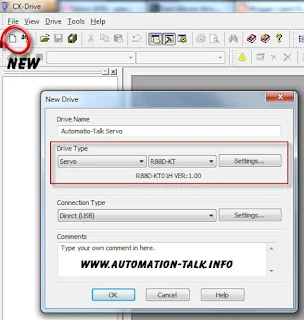

How to Change Servo Drive Parameter using Omron CX Drive

In industrial automation, we install and program many servo motors and drive in industries every day and so sometimes it becomes very problematic to set each and every drive with the display panel. So to make this an easy process, you can also use servo drive software to make changes or set new parameters through your laptops. Today let me tell you about CX drive, which is Omron product and by which you can program your drive without touching display panel. Almost all the automation product manufacturing company provide servo drive software so you can check with your drive provider. Subscribe to Automation-Talk by Email.

Required Conditions

1. You must have CX-Drive installed on your laptops/desktops.

2. Servo drive should be connected to set or change parameter's online.

In this example we have selected R88D servo drive.

Recommended Reading: How to Reduce Electro-Magnetic Interference in Servo Drives

Steps to Change Servo Drive Parameter Using Omron CX Drive

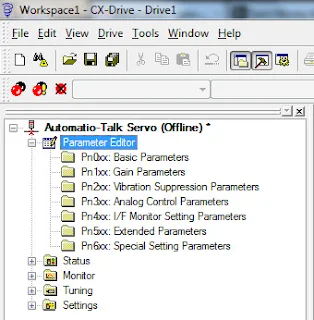

1. Start CX Drive software in your laptop. If you have installed CX-One software and all its component, then it will be under Omron -- CX-One -- CX-Drive

2. Now click on new and make your servo drive project. Here you will have to select a servo drive model from the list and you can also set the maximum rating of the drive through settings.

3. Now expand your new project and click on Parameter Editor. In parameter editor, you can even choose from different parameter list like basic parameters, gain parameters, vibration suppression parameter, analog control, special setting parameter etc.

4. Suppose we first want to set basic parameters, then just click on it and you will be shown all the basic parameters of the servo drive.

Now suppose we want to change control mode of the drive, then we can use parameter Pn001 and can set its value as required for the project. See the example below.

Similarly, you can change any parameter of servo easily.

Now to transfer this new setting to your drive, just go to transfer, which is under drive tab and transfer the settings to your drive. And if you are not connected to your drive you can also save your setting for after use. I like this method because you can use the same settings for every drive and you can save your project parameter wise, which saves your precious time.

If you like our articles, please consider them sharing with your friends and do like us on Facebook. You can also share your views and feedback through comments.

Dec 4, 2018

How To Find PPR and Maximum Frequency of Encoder

Encoder comes with a specified PPR i.e pulse per Revolution and Maximum Frequency output of the pulses given by encoder. Generally, encoders are mounted on the shaft of the conveyor, so according to the resulting RPM we should select the encoder with a proper PPR and output frequency.

How to Find PPR and Maximum Frequency of Encoder

The encoder is interfaced with the PLC for counting the pulses given by encoder and taking the feedback. PLC inputs also have a frequency range for the pulses which it can accept. So calculating the frequency of pulses by the encoder is important in an application. Below is the formula to find the Max. The frequency of encoder in from the PPR and RPM.

Max. Frequency of encoder in Hz = (RPM / 60) * PPR

So if the encoder is mounted where the RPM = 2000 and PPR of the encoder is 360 the frequency of encoder will be 12KhZ. So we could find out that our PLC will be able to count pulses with this frequency or not.

Recommended Article: Using High Speed Counter in Omron PLC

Let us also see the difference between Single turn and Multi-Turn encoders.

In single turn Encoder, the output code is repeated after every single revolution of the encoder shaft i.e we can not actually determine how many turns have encoder made 1 or 1000.

In Multi-turn Absolute encoders, the output is unique for each revolution or for every shaft positions up to 4096 revolutions and we can get to know that the numbers of rotation of Encoder.

For more updates on Encoders you can subscribe to get all information in yours Inbox. Subscribe to Automation-Talk by Email.

Aug 30, 2018

How to Save Energy using VFD/Inverter/AC Drive

Variable Frequency Drive or VFD is a power electronics device which has revolutionized the Electrical Industry. VFD have made possible the speed and frequency control of the AC Motor. VFD gives a load of other advantages other than speed control. VFD is the best starting method for AC Motor. Also, the energy saving feature in drive makes an added advantage for saving the electricity and thus reducing the cost.

Save Energy by Using Baldor VFD

Baldor VS1MD series VFD have a special feature through which we can save energy and thus reduce the cost of electricity bills. In almost all the industries where there are many motors, most of the electricity bill is raised from current consumption by these motors. But by installing Baldor VFD we can get up to 30% energy savings and thus the cost of the drive can be recovered in just 1 Year.

All the drives have PWM output, so it means that even if we don’t set the parameter we will get the energy savings and that is for sure. If we compare two motors of same ratings, for example, there are two motors of 10 HP Motor A and Motor B. Motor A is run through Star Delta Starter and Motor B is through VFD.

Both the Motors A and B are used in the same application with the same load condition and the same environment. If we install an Electric Meter and monitor the Units consumption then we will find that there will be around 20 to 30% lesser electric units consumed by Motor B which is run through VFD.

Parameter Setting in Baldor VFD for Energy Savings

To boost the energy savings in Baldor VFD, there is one Parameter. Parameter Number F40, in this put the value in between 0 to 30. It adjusts the output voltage according to the load status. It is set as a percent of a maximum output voltage.

When there is any pump or fan application, setting this parameter can dramatically reduce energy consumption by decreasing the output voltage with light loads or load behavior.

We will be discussing more about VFD Application and its advantages, so till then subscribe to Automation-Talk by Email, so that you can get all the latest updates.

Aug 7, 2018

Understanding Torque and Its Simplest Explanation

In the past few topics of AC Motor basics we have seen about general motor terms, different types of motor load and the Calculation of Synchronous speed from Poles. We all frequently use term called Torque in our day to day work life. But, do we really know the actual meaning of "Torque". We got many request from our readers to explain the term torque in simple words. So get a cup of coffee and sit back. Subscribe to Automation-Talk by Email.

What does Torque Signify?

In our industrial applications when we have to select the driving motor for any load we are always concerned about the horsepower, but believe me the real driving force is TORQUE and not horsepower. In the simplest word torque is the twisting/rotational force exerted by the drive on the load. Now let us take a simple example.

Do you remember that sometimes you try to open the lid or open a bottle but after so many tries it does not open? Do you know the reason why it doesn't open? Because we are unable to supply or apply the adequate torque to open the lid. The solution for this can be a) grit our teeth and try harder, b) use a rubber pad, or cloth, to increase the ability to transmit torque without slippage, or c) use a mechanical device to help multiply our torque producing capability. If still, it doesn't open then give it to some stronger person!!

Well, the main motive behind the above example was just to make u feel something about torque. We are always confused among HP and Torque. Now let us suppose that after so much try also the lid did not open and now we will wrap a cord around the lid and supply a force to the end of the cord through a scale. See the below diagram.

Example for Torque Calculation

Can we tell the torque required in this case? Yes, we can, the torque requirement will be the force as depicted on scale multiplied by the radius of the lid. For example, if the reading of force on the scale is 17 lbs( at the time of breakaway of lid) and the radius is 3 inches then the torque requirement would be:-

T = F * R = 17 * 3 = 51 lb.inches

Simplest Explanation of Torque

However, the above example gives a clear illustration of the torque but lets us discuss one more thing which is observed in industrial applications. If we recall the above example then we can derive one more term called "Stiction". Stiction can be defined as the amount of torque required to make a load lose and start the first revolution. Stiction is nothing but only the second name of the breakaway torque and frankly speaking for every industrial application the breakaway torque requirement of any load is greater than the continuous torque requirement for running the machine.

The amount of "stiction" present in a machine will be dependent on the characteristics of the machine as well as the type of bearings that are used on the moving parts. Below you can see a picture in which the breakaway torque requirement of different machines is shown.

So, we have got now a clear view of the torque and its characteristics, in the next few days we will try to see more different types of torques and detailed explanation of torque in a simple way. Till then you can subscribe to get all latest updates via Email.